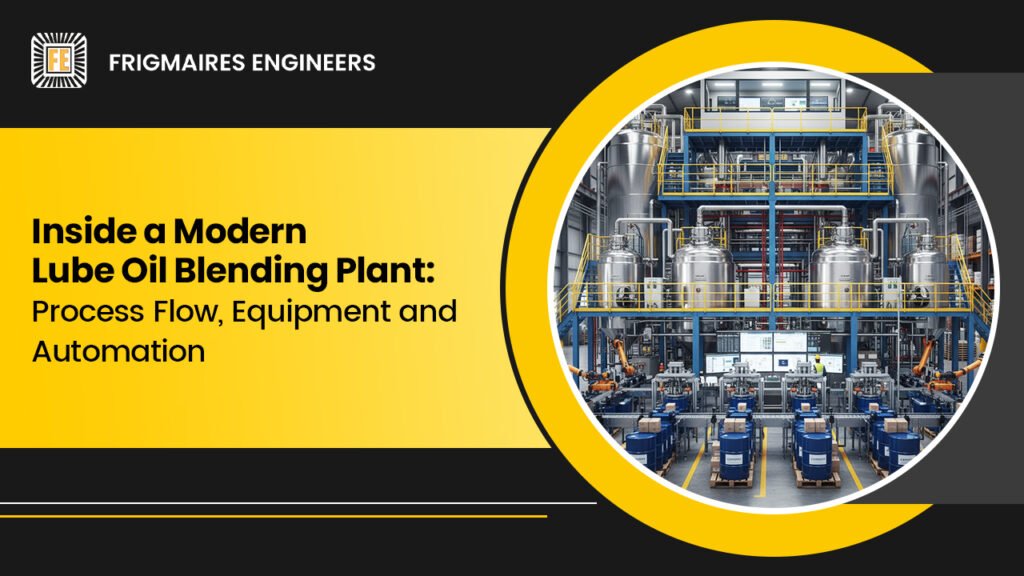

In today’s fast-paced lubricants industry, manufacturers must deliver consistent product quality while optimizing cost and efficiency. A modern lube oil blending plant (LOBP) achieves this balance through smart process design, precision equipment, and automation. Here’s a closer look at how such a facility operates—from base oil handling to automated packaging.

- Base Oil and Additive Handling

Every lubricant begins with base oils (mineral or synthetic) blended with performance additives. These additives improve viscosity, prevent wear, resist oxidation, and enhance engine cleanliness.

At the plant’s front end, raw materials arrive in bulk and are stored in dedicated tanks. Each tank is fitted with level sensors, temperature control, and inert gas blanketing** to preserve product integrity. Additives, stored in heated or agitated vessels if needed, are tracked through an automated tank farm management system that ensures accurate transfers and complete traceability.

- Additive Dosing and Metering

Precision in dosing is the key to a successful lubricant formula. Modern plants use flow meters, load cells, and PLC-controlled pumps to measure exact quantities of base oils and additives.

Automation ensures each component is added in the correct sequence and ratio, minimizing human error. For example, viscosity index improvers or polymeric additives may be pre-blended in small vessels before being metered into the main batch. This not only enhances accuracy but also reduces production time and waste.

- Blending and Mixing Process

The heart of any blending plant is its mixing system. Two common types are used:

Batch blending, where ingredients are mixed in large vessels equipped with agitators and heating jackets.

Inline blending, which continuously mixes components as they flow through static or dynamic mixers.

Temperature control is critical—certain additives dissolve better at higher temperatures. Sensors and heating systems maintain uniform conditions, ensuring a consistent blend. Once mixed, the product may rest in a buffer tank before filtration and quality testing.

- Filtration and Quality Control

Before packaging, the blended oil is filtered to remove any impurities or solid particles. Cartridge or mesh filters are standard at this stage. Samples are then tested for **viscosity, density, flash point, and additive concentration in an in-house lab.

Quality data is logged digitally, creating a complete batch history for traceability. Only after passing all specifications does the lubricant move to the finished product storage area.

- Packaging and Dispatch

The certified product is transferred to the filling and packaging line, which may handle bottles, pails, barrels, or bulk tankers. Modern filling machines use mass or volumetric flow meters for precision.

Automated labeling, capping, and palletizing systems ensure speed and consistency, while barcoded batch numbers link every container to its production data. This integration between production and logistics enhances accountability and efficiency.

- Role of Automation

Automation is what transforms a conventional plant into a modern, high-efficiency operation. Systems like **PLC, SCADA, and MES** manage recipes, monitor process parameters, and generate production reports in real time.

Key automation functions include:

* Recipe management: digitally stores and executes blend formulations.

* Tank farm monitoring: tracks levels, flow, and temperature.

* Process control: adjusts pumps, valves, and heating systems automatically.

* Data logging: maintains electronic batch records for audits and quality assurance.

Automation improves accuracy, reduces manpower requirements, and enables quick changeovers between lubricant grades—boosting overall plant productivity.

- Process Flow Summary

A simplified workflow in a modern LOBP looks like this:

- Raw materials received and stored.

- Additives and base oils precisely dosed.

- Blending/mixing under temperature control.

- Filtration and quality testing.

- Finished product storage.

- Automated filling and packaging.

- Dispatch and digital documentation.

Each step is seamlessly connected through automation, ensuring smooth operation from start to finish.

- Benefits and Future Trends

Benefits of modern blending plants:

* Consistent product quality through precise dosing and mixing.

* Reduced waste and downtime via automated control.

* Full traceability and compliance with ISO/API standards.

* Flexibility to produce multiple lubricant grades efficiently.

Emerging trends include inline blending for higher throughput, IIoT-enabled monitoring, predictive maintenance, and **energy-efficient heating systems. Modular, skid-mounted units are also gaining popularity for faster installation and scalability.

Conclusion

A modern lube oil blending plant is far more than a mixing facility—it’s an integrated system combining engineering, chemistry, and automation. Each process stage, from raw material handling to final packaging, is optimized for precision, safety, and sustainability.

For companies like Frigmaires, which design and supply turnkey lube oil blending systems, understanding and implementing these advanced technologies ensures clients achieve superior quality, consistency, and operational excellence.