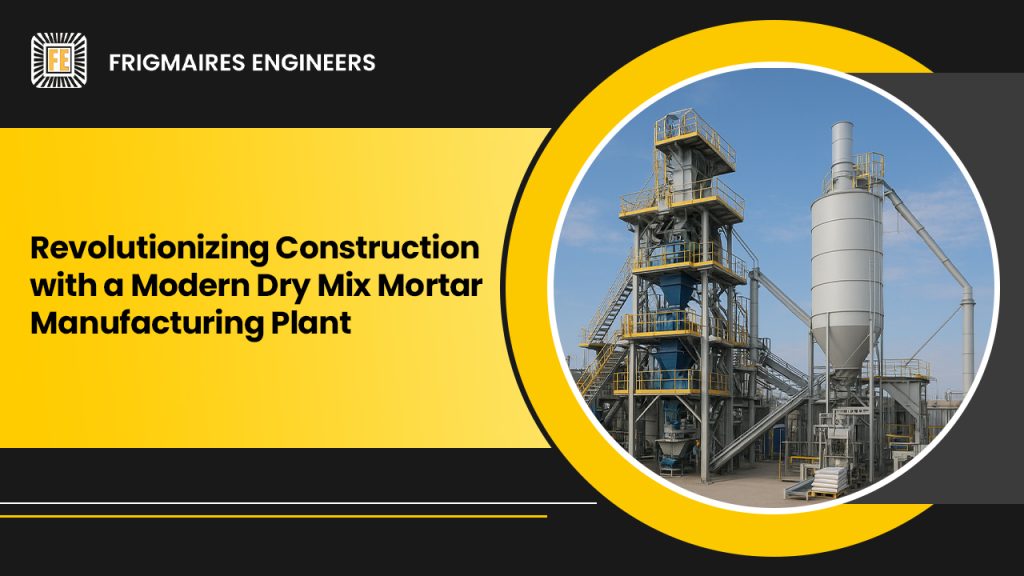

Introduction: Why Dry Mix Mortar is the Future of Construction

The construction industry is rapidly evolving, demanding higher efficiency, precision, and quality in every project. One innovation driving this transformation is the dry mix mortar manufacturing plant. Unlike traditional on-site mixing methods, a dry mix mortar plant ensures consistent quality, saves time, and reduces wastage—making it a preferred choice for large-scale and sustainable construction projects.

At Frigmaires Engineers, we specialize in providing state-of-the-art dry mix mortar manufacturing plants that meet global standards, ensuring durability, efficiency, and profitability for our clients.

What is a Dry Mix Mortar Manufacturing Plant?

A dry mix mortar plant is a facility designed to produce pre-mixed mortars used in construction. These mortars are formulated with precise proportions of cement, sand, additives, and other materials, ensuring uniform quality and performance.

Dry mix mortar is widely used in:

- Plastering

- Masonry work

- Tile adhesives

- Grouts

- Repair mortars

Key Features of a Modern Dry Mix Mortar Plant

A well-designed dry mix mortar plant from Frigmaires offers:

- Automated operations for precise mixing and batching.

- Dust-free handling systems ensuring a clean and eco-friendly production environment.

- Customizable recipes for different mortar applications.

- High energy efficiency with minimal maintenance.

- Compact design that saves floor space. Benefits of Investing in a Dry Mix Mortar Plant

- Quality Assurance

Every batch is consistent, ensuring reliability and superior performance.

- Cost Efficiency

Reduced labor, material wastage, and faster execution.

- Versatility

Wide range of applications in plaster, masonry, and tile works.

- Sustainability

Lower dust pollution and environmentally friendly processes.

- Market Demand

Rising demand in real estate and infrastructure sectors ensures growth potential.

Why Choose Frigmaires for Dry Mix Mortar Manufacturing Plants?

With decades of experience in engineering excellence, Frigmaires Engineers is recognized as a trusted manufacturer of dry mix mortar plants worldwide.

- Proven Expertise: Customized plant designs to suit your production needs.

- Global Standards: Machinery manufactured with international quality benchmarks.

- After-Sales Support: Training, installation, and technical assistance.

- Turnkey Solutions: From concept to commissioning, we handle everything.

Applications of Dry Mix Mortar in Modern Construction

Dry mix mortar is a versatile product with growing applications such as:

- Internal & external plastering – Smooth finishes with durability.

- Masonry bonding mortar – Strong adhesion for bricks and blocks.

- Tile adhesives & grouts – Enhanced bonding for tiles and ceramics.

- Specialty mortars – Fireproof, waterproof, and repair mortars.

FAQs about Dry Mix Mortar Manufacturing Plant

Q1: What capacity options are available for dry mix mortar plants?A: Plants are available in capacities ranging from 5 TPH to 100 TPH, depending on production requirements.

Q2: How much space is required for installation?

A: A compact plant can be installed in as little as 200 m², while large-scale plants require more.

Q3: Is the plant fully automated?

A: Yes, modern plants from Frigmaires are semi-automatic or fully automatic, depending on customer needs.

Q4: What raw materials are used?

A: Cement, sand, additives, and polymers are the key raw materials.

Q5: How long does it take to set up a plant?

A: Depending on size, installation can take between 2 to 6 months.

Q6: Is dry mix mortar eco-friendly?

A: Yes, it reduces dust, wastage, and water consumption, making it environmentally sustainable.